I adjusted the rear brake shims on my 550 Oliver tractor, and it improved braking efficiency. The shims ensured smooth brake engagement and even wear. Now, the brakes work reliably.

Rear brake shims on a 550 Oliver tractor help maintain brake alignment and smooth performance. They ensure even wear and reliable braking. Regular checks keep your system running safely.

Stay tuned as we explore rear brake shims on a 550 Oliver tractor! We’ll cover their importance and how to keep your brakes in top condition.

What Are Rear Brake Shims on a 550 Oliver Tractor – Complete Guide!

Definition of Rear Brake Shims

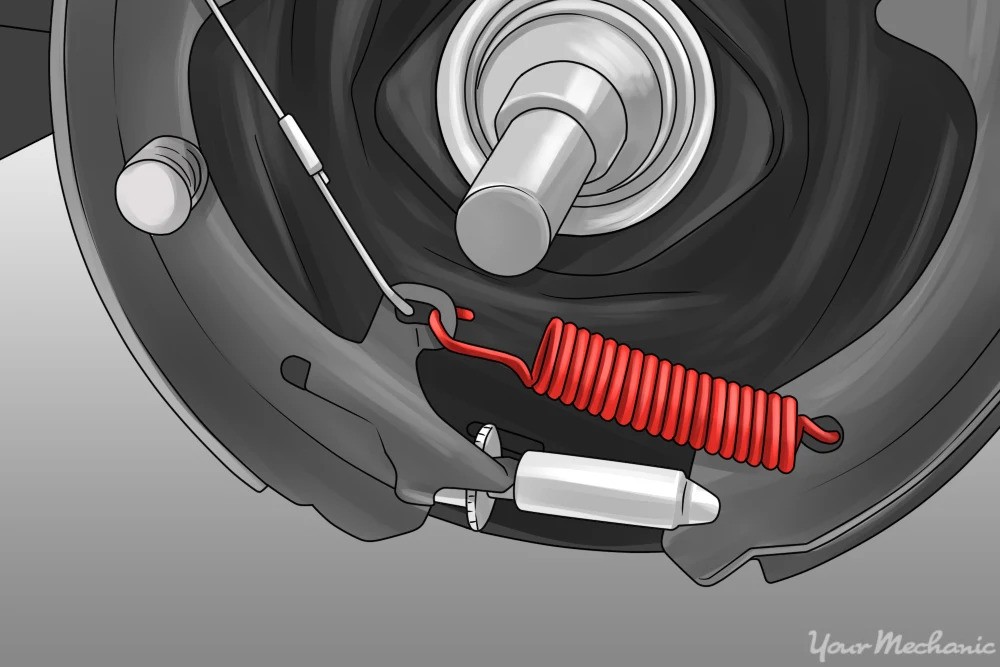

Rear brake shims are thin metal plates located between the brake shoes and the brake drum in the rear braking system of a 550 Oliver tractor. These shims are designed to adjust the spacing between the brake shoes and the drum to ensure that the brake system functions optimally. Their purpose is to maintain proper alignment and prevent the brake shoes from dragging on the drum, which could lead to wear and decreased braking efficiency.

How Rear Brake Shims Work

Shims help to achieve the correct clearance between the brake shoes and the brake drum. This alignment ensures that the brake shoes engage smoothly when the brake pedal is pressed. Without properly adjusted shims, you may experience issues such as uneven brake wear, spongy brakes, or even reduced braking efficiency. Rear brake shims play an important role in preventing such problems, ensuring your tractor’s braking system is as effective and safe as possible.

The Role of Rear Brake Shims in Braking Efficiency – Key Insights!

Ensuring Optimal Braking Performance

The proper alignment of rear brake shims ensures that the brake shoes make even contact with the brake drum, which is essential for achieving optimal braking performance. If the spacing is off, it can lead to uneven braking or difficulty stopping, especially under heavy loads. Properly adjusted brake shims help to create a smooth, reliable brake response every time.

Prevention of Uneven Wear

By maintaining the correct spacing and alignment, brake shims prevent uneven wear on both the brake shoes and the drum. Uneven wear can drastically shorten the lifespan of these components and lead to more frequent repairs. A well-maintained brake system with properly adjusted shims helps avoid these costly repairs.

Also Read: TraceLoans – How It Works and Why You Need It In 2025

Enhanced Safety

Proper brake function is crucial to the safety of your 550 Oliver Tractor. With correctly adjusted rear brake shims, the braking system will perform efficiently, whether you’re hauling heavy loads, working on inclines, or operating in difficult conditions. Ensuring your rear brake shims are in top condition can significantly improve the safety and longevity of your tractor.

Rear Brake Shims – Time for Adjustment or Replacement!

Common Symptoms of Improper Shim Adjustment

It’s essential to inspect your rear brake shims regularly to ensure they are functioning properly. Common signs that your rear brake shims need adjustment or replacement include:

- Reduced Braking Efficiency: If you notice that your tractor takes longer to stop or requires more force to brake, the shims may be improperly adjusted.

- Uneven Wear: Inspect the brake shoes and drum for signs of uneven wear. This often indicates that the shims need attention.

- Unusual Noises: Grinding, squealing, or other unusual noises when applying the brakes can indicate that the shims are misaligned or damaged.

By recognizing these signs early on, you can address issues before they become serious, saving time and money on repairs.

550 Oliver Tractor Rear Brake Shim Adjustment Guide!

Tools Needed

Before you begin adjusting your rear brake shims, make sure you have the following tools:

- Wrenches and screwdrivers

- Jack and jack stands

- Safety gear (gloves, goggles)

- A service manual for the 550 Oliver Tractor for specific clearance settings

Step-by-Step Guide to Adjusting Rear Brake Shims

- Preparation: Park your tractor on a level surface, engage the handbrake, and disconnect the battery to ensure safety. Use a jack to lift the rear of the tractor and secure it with jack stands.

- Remove the Rear Wheels: Loosen and remove the rear wheels to expose the brake assembly.

- Inspect the Brake Shims: Examine the condition of the shims. If they are damaged, excessively worn, or out of alignment, replace or adjust them accordingly.

- Adjust the Spacing: If the shims need adjustment, add or remove shims as necessary to achieve the correct spacing between the brake shoes and the drum. Refer to the service manual for the exact clearance specifications.

- Reassemble and Test: After reassembling the brake components, reinstall the wheels, reconnect the battery, and test the brakes at a low speed to ensure everything is working correctly.

Also Read: Yexex.GitHub – A Complete Guide In 2025

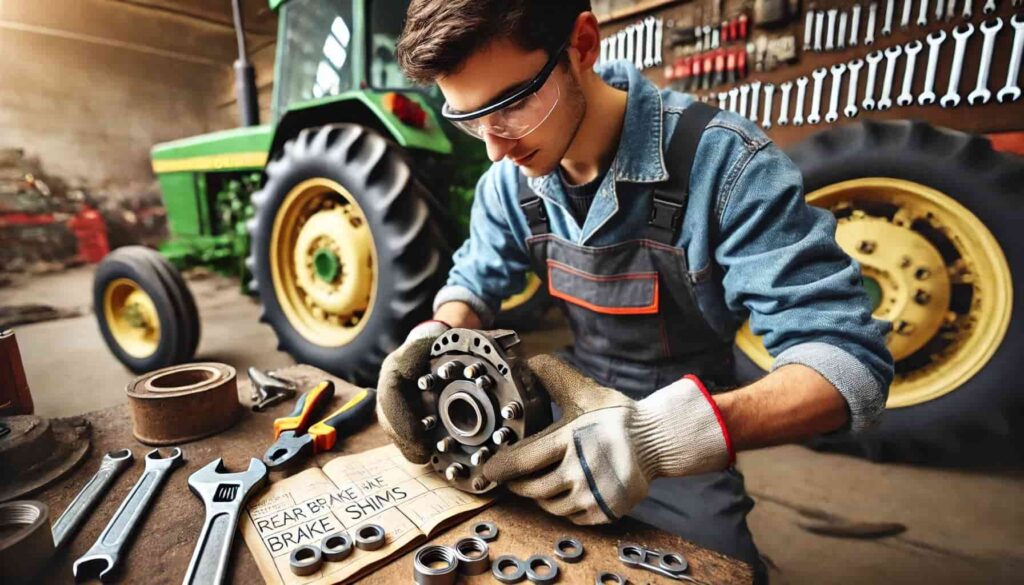

Visual Support:

Consider including an image or video showing the step-by-step process, from wheel removal to shim adjustment.

Top Maintenance Tips for Rear Brake Shims – Keep Them in Check!

Routine Inspection

Regular inspection of your rear brake shims is essential for long-term performance. Check your shims during routine maintenance, ideally every 100 operating hours, or whenever you perform brake system checks.

Cleaning the Brake Assembly

Dirt and debris can interfere with the alignment of the brake shims, so it’s important to clean the brake assembly regularly. Use compressed air or a clean rag to remove dirt from the brake drum and shoes.

Using OEM Shims

When replacing your rear brake shims, always use high-quality OEM shims. These parts are designed specifically for the 550 Oliver Tractor, ensuring compatibility and optimal performance. Using aftermarket or universal shims may lead to misalignment and premature wear.

Troubleshooting Rear Brake Shims – Common Issues and Fixes!

Brake Drag

If your tractor’s brakes feel like they’re dragging, the cause may be excessive shim thickness. Try removing one or two shims and test the brakes again to resolve the issue.

Uneven Braking

Uneven braking can occur if the shims are misaligned or damaged. Inspect and reposition the shims to ensure that they are correctly placed and not interfering with the brake shoes or drum.

Spongy Brakes

Spongy brakes can indicate insufficient shim thickness. Add shims incrementally until the correct clearance is achieved, restoring the brake response.

Noisy Brakes

Grinding or squealing noises usually mean that the brake shoes are contacting the drum incorrectly. Check for damaged or misaligned shims and replace or adjust as needed.

Essential Safety Tips for Handling Rear Brake Shims!

Wear Proper Safety Gear

Always wear gloves and safety glasses to protect yourself from debris and sharp objects while working on your tractor’s brakes.

Use Proper Jacking Equipment

Ensure that your jack and jack stands are rated for the weight of your tractor to avoid accidents when lifting the rear of the vehicle.

Follow Manufacturer Guidelines

Consult the Oliver 550 service manual for torque specifications and specific safety guidelines related to brake shim adjustments.

Also Read: The Ultimate Guide to www.eyexconcom – Your Path to Excellence

Frequently Asked Questions

How often should I check rear brake shims on a 550 Oliver Tractor?

It’s recommended to inspect your rear brake shims every 100 operating hours or during routine maintenance sessions.

What happens if I don’t adjust rear brake shims?

Ignoring shim adjustments can lead to uneven brake wear, decreased braking efficiency, and potential safety issues.

Can I use universal shims for the 550 Oliver Tractor?

While universal shims may fit, it’s advisable to use OEM shims to ensure the best compatibility and performance.

How do I know if my rear brake shims are too thick?

If the brakes feel like they are dragging or the tractor has reduced braking efficiency, your shims may be too thick.

Why does my tractor have two brake pedals?

Two brake pedals help control each rear wheel separately, making turning and controlling the tractor easier.

Where are the brakes on a tractor?

The brakes are usually on the rear wheels and can be controlled by separate pedals or a single pedal.

How do you adjust the brakes on a Kubota tractor?

To adjust the brakes on a Kubota, you need to adjust the brake linkage using special bolts. Check the manual for exact steps.

Where are tractor brake pedals located?

The brake pedals are usually on the floor near your feet, either separate for each wheel or combined.

Why do tractors have left and right brakes?

Left and right brakes let you control each rear wheel separately, which helps in turning or controlling the tractor better.

Is adjusting brake shims difficult?

With the right tools and guidance, adjusting rear brake shims on a 550 Oliver Tractor is a straightforward process.

Can worn-out rear brake shims cause braking issues?

Yes, worn or damaged shims can cause inefficient braking, leading to safety risks and the need for more frequent repairs.

Conclusion

Rear brake shims on a 550 Oliver Tractor are essential for maintaining an efficient and reliable braking system. Regular inspection, proper adjustment, and timely replacement of these small components can save you money on repairs and ensure your tractor’s performance is top-notch. By following this comprehensive guide, you can keep your tractor’s braking system in great shape for years to come, ensuring both your safety and the longevity of your equipment.

Oliver is a skilled writer and content strategist at PreferKit, specializing in educational resources and language tips. With a passion for clear, engaging content, he simplifies complex topics while ensuring accuracy and SEO excellence. Follow his work for expert insights! 🚀